Pump Station Inspection and Maintenance: Our 30-Point Report

Published on June 25, 2020

Our maintenance inspections normally cover a 30-point inspection, ensuring that no small issue becomes a large one. The following represent the major components we look at during each inspection:

Our 30-point Pump Station Inspection Report is Standard for all Commercial Pump Stations

Wet Well

Grease Build-Up: Check all surfaces for grease build-up. Any surface which may cause sewage to cool (concrete, metal, plastic, etc) can be a surface which accumulates grease. This buildup should be cleaned by a pump truck at each service, either by powerwasher or mechanical method. Furthermore, grease should be removed from the system entirely, as pushing it downstream will simply cause the grease to build up at a downstream location, eventually causing an upstream blockage.

Check out this clip from the City of Hampton on how they clean their pump stations:

Floats: Floats should be at their designated elevations, free to operate as designed. Sometimes floats become tangled or hung-up on trash, grease, or other components. Float cables should be managed as well.

Seal Flange: The pump should seat on the seal flange without obstruction or gap. If the pumps are removed and reseated, it is important to make sure that seal remains in-tact at the beginning of the next service cycle.

Wench and Mounting Stand: Many large pumps require a lifting mechanism to raise and lower at services. This mechanism needs to be inspected, oiled/greased, and monitored for strains or weaknesses in the chain or cable.

Electrical Cables: Cables should be kept organized and tied-off in secure locations where available. Seals should be monitored to make sure they are in-tact. Rubber insulation should be inspected for any signs of wear – nicks or scratches can lead to overload failures or other electrical problems.

Pumps

Pump Manufacturers will require a regular maintenance program in order to maintain warranted status. A few major manufacturers are below with model-specific recommendations. Any pump station inspection and maintenance service should include the full requirements of your manufacturer, at a minimum.

Major Manufacturers

- KSB

- Goulds

- Gorman-Rupp

- Smith and Loveless

- Barnes/Crane

- Liberty

- Pentaire

- Zoeller

- HOMA

- Grundfos

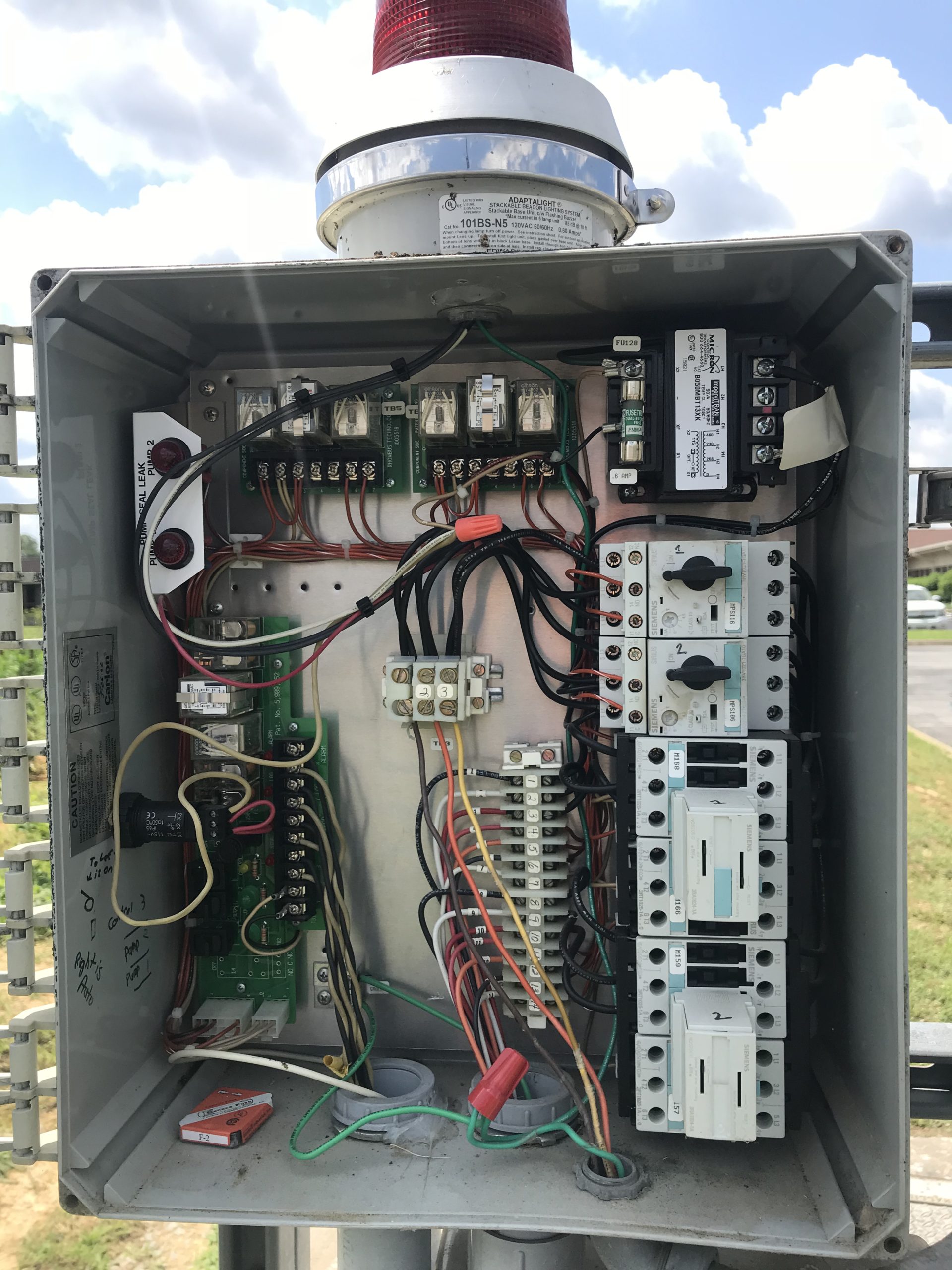

Pump Controls

Float Switches: Floats in the tank tell the pumps when to engage and disengage. Mercury-filled cavities attached to the floats move when the float moves, causing an electrical signal to tell the control panel when to turn the pumps on and off.

Control Panels: This component is brain of the pump station. Making certain the control panels are in top working order is imperative to pump station maintenance.

Moisture Sensors: Keep your pump motor operational. The environment a sewage pump operates in is wet – keep the pump dry.

Contacts: Both the starter contacts and the alternator contacts should be inspected to make sure connections are good.

Breakers: A failure to maintain the breakers can allow a simple surge to wipe out your controls or pumps.

Autodialer

Auto dialers: Tested in remote and on-line. Useful when a pump station goes into a “high water alarm” situation. An autodialer communicates the alarm to a phone number or email address. This is an especially critical component for pump stations with extremely heavy flow and/or pump stations located in socially or environmentally sensitive areas. While a regularly scheduled pump station inspection and maintenance service is the best line of defense, an autodialer will be on-call 24/7 should any issue arise.

Electrical

Main Disconnects: The main disconnect allows for the quick, efficient service of your pump station. It also allows for everything to stay online when the work is to be done.

Lights: Lights are important components of the alarm. Site and building lights may also need to be maintained.

Transfer Switches (see Generator item, below): An operational transfer switch enables the backup generator. A faulty one breaks an important link in that chain.

Flowmeter

Calibration: If you use a flowmeter to calculate the rate at which sewage flows either into or out of the station, you need to make sure that it is properly calibrated at installation, and at whatever service interval is required by the manufacturer.

Debris/Buildup: Anything which will occlude or obstruct the sensor will cause the flowmeter to read incorrectly.

Generator

Cycle System: The system should be cycled at least once for every service. Any issues which may arise should be tended to in quick order.

Check Oil/Filter: Check oil and replace with filter when needed.

Exhaust System: The exhaust system should be operational and unobstructed.

Valve Vault

Air Relief Valve: the ARV may serve an important role in keeping your pump in good, operating condition. See cavitation.

Plug/Check Valves: Valves should be opened and closed to ensure operation when needed. Valves have a tendency to seize or become stuck if not used regularly.

Sump Pump: Your vault may have a sump pump for rain or groundwater. Make sure the valve vault stays dry with a working sump pump or sump drain.

Building and Grounds

Heater: Any above-ground piping is succeptable to freezing. A heater is required in many situations to avoid frozen and busted pipes. You may also consider putting OCTG coatings on the pipes to add protection against rust and other harmful materials.

Ventilation System: Both health requirements and heat and humidity requirements mean a functioning ventilation system. Sometimes this is as simple as a set of working louvers. Sometimes the addition of a small fan.

Plumbing: Due to the important task it performs, it is important to keep plumbing well maintained. Piping in and around the building may serve to keep grounds tidy or have a functional role in the pumping action of the station. Make sure no plumbing is leaking and that all connections are secure and to-code. If there are any leaks, get plumbing assistance right away to fix them.

Grounds & Housekeeping: a clean and tidy pump station is a healthy pump station. We’ve seen pump stations double as vagrant homes for both people and beasts. Grass, trees and shrubs should be maintained for ease of access and to maintain a proper operating buffer from vegetation.

The importance of pump station inspection and maintenance…

Stay out of the news – contact us here today to schedule your pump station inspection and maintenance.